Subsurface Damage

SUBSURFACE DAMAGE

Why we are concerned about it, and so should you.

Subsurface damage is a hidden but critical factor affecting the performance, durability, and laser resistance of nonlinear crystals. Controlling SSD during fabrication is essential for achieving high-quality optics capable of sustaining intense laser fields without degradation.

Optical fabrication operations such as grinding and polishing leave traces in the material below the surface being worked. These stresses are known as SSD, Subsurface Damage. Some are invisible. They can lead to surface decay, scattering of laser light, and premature laser induced damage (LID).

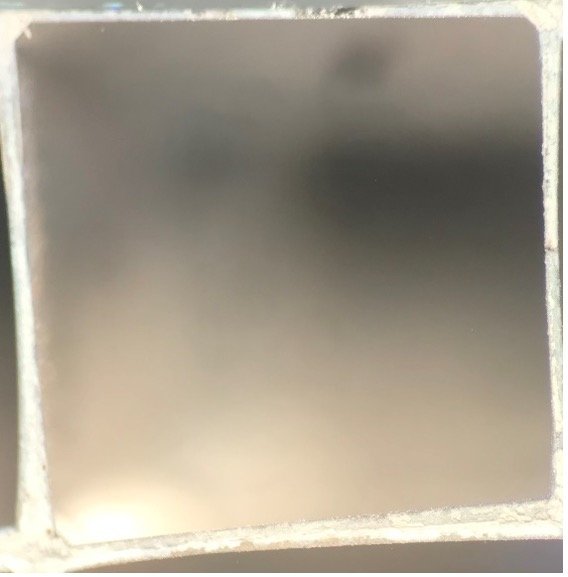

An optic’s surface can appear to the naked eye to be smooth and fully polished out. Closer examination can reveal the remains of subsurface damage. In many cases SSD may not be apparent at first yet become obvious after exposure to the surroundings. For instance, sometimes moisture in the air can erode the surface of a polished optic.

GAMDAN Optics, Inc. uses a proprietary process of iterative controlled removal. The “Super Polished” surfaces that result show no degradation after eight months of storage under the same conditions as the one in Figure 2. It is no surprise that customers have found that GAMDAN Optics, Inc. nonlinear crystal substrates last longer and have superb laser damage resistance.

GAMDAN Optics, Inc. Super Polished crystals will give your application the longest lifetime possible. We pride ourselves on client satisfaction!

Please contact us for further questions you may have on Subsurface damage or to discuss the contents of this article.

Figure 3 - Gamdan Optics Super Polished

Figure 1 - Traces of SubSurface Damage in Micrscope.

Figure 2 - Surface left exposed causing SubSurface Damage